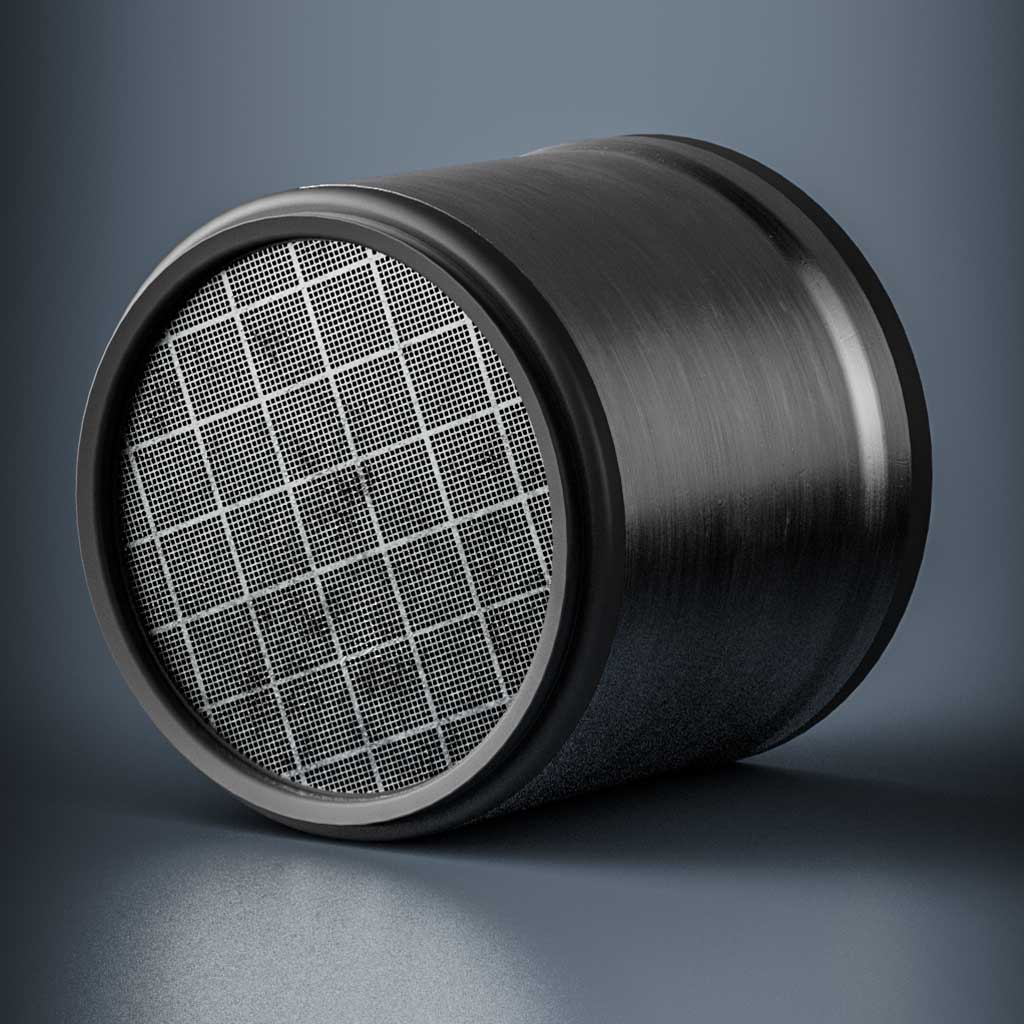

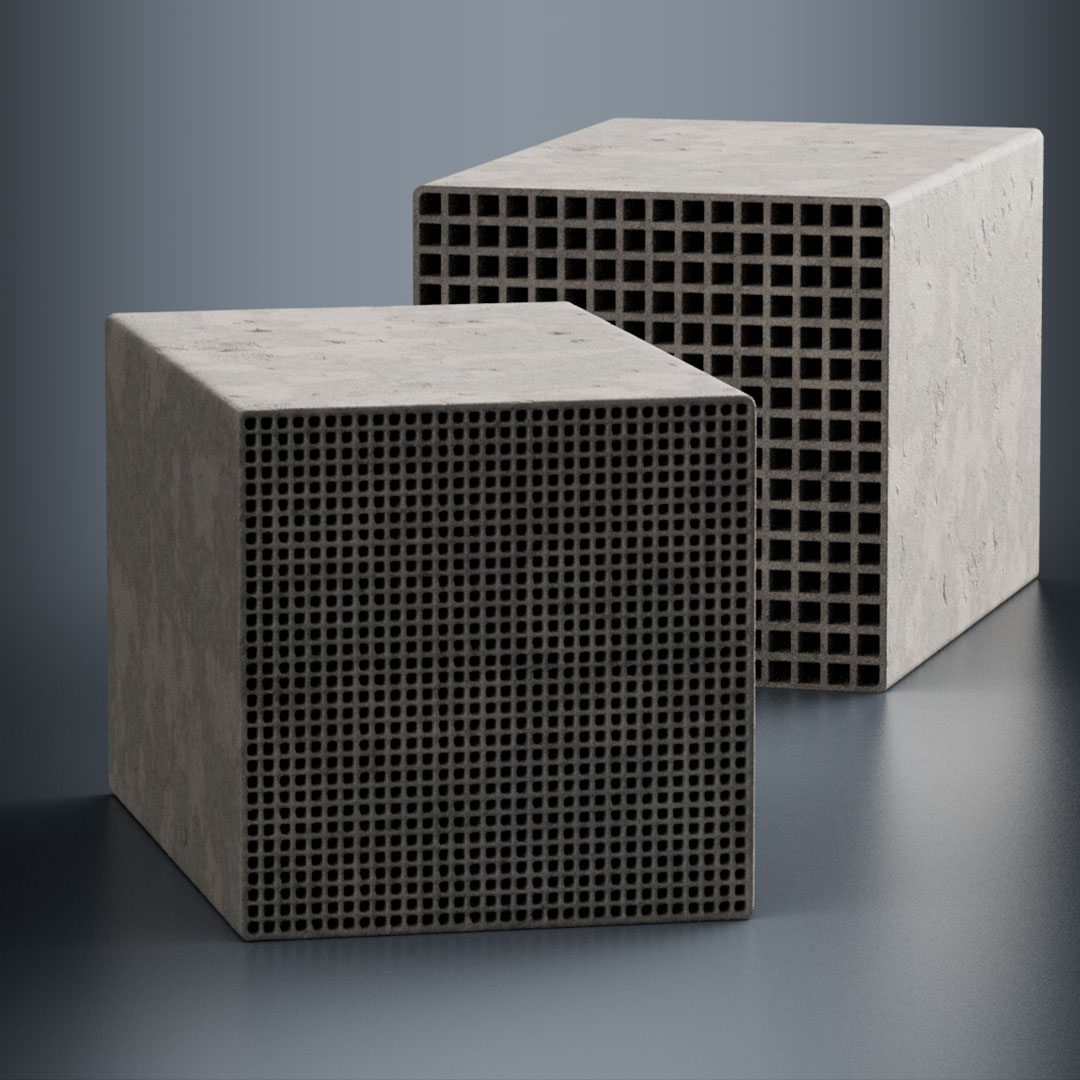

Car catalytic converters are typically composed of a ceramic substrate coated with precious metals such as platinum, rhodium, and palladium. These metals serve as catalysts, accelerating the reactions necessary for exhaust gas purification. The ceramic substrate allows the catalyst to withstand high temperatures, while the precious metals perform the required catalysis.

The recycling process begins with the dismantling of the catalytic converter from the vehicle, separating the ceramic substrate from the metallic carrier materials. Subsequently, the ceramic material is crushed, and the contained precious metals are extracted from the washcoat. The extracted precious metals can then be utilized for the production of new catalytic converters or other products. This helps reduce the demand for primary precious metals and diminish dependence on imported raw materials.